3D printed kippahs

The 3D printed Euclidean kippah, modelled by J.

Last fall, while on sabbatical, I created a couple of 3D printed kippahs (well, kippot, actually). Then out of the blue, in the past couple of weeks they received some attention online. It started with an interview in Inside 3D Printing magazine, which was inspired by the writer’s interest in the kippahs but grew to encompass my 3D printing adventures in general. From there, I believe it was picked up on Jewcy, a Jewish culture website. That led in turn to interviews on an NPR blog and in the Jerusalem Post. It was an interesting week. Several times I wondered why people didn’t simply read the blog post I had written about the kippahs. Of course, I then realized that I hadn’t written one. Given that I would generally like to document my work online, I herewith correct that omission.

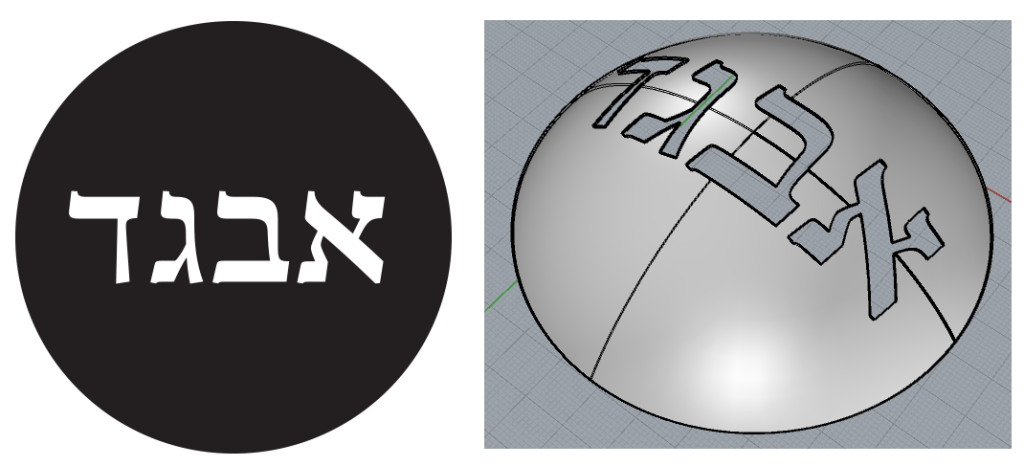

I think the first step in the process was to work out the mathematical and technical details needed to create 3D models that would work for printing (more below). Once I knew that my approach was feasible, I began to explore the design space of kippahs. As a first step, I considered patterns of six-pointed stars, because the Star of David is a simple geometric figure that’s strongly associated with Judaism. After some tinkering, I came up with four initial design concepts:

- A simple Euclidean kippah, in which a repeating pattern is mapped directly onto the rounded surface;

- An “inverted” kippah, in which the Euclidean design is passed through a mathematical transformation to create a spiralling arrangement of ever-diminishing stars towards the crown;

- A hyperbolic kippah, based on a hyperbolic tessellation with six-pointed stars; and

- A “multiscale” kippah, in which stars are nested in the spaces between the points of larger stars (inspired in part by Phil Webster’s lovely work on the subject).

I wasn’t happy with the hyperbolic kippah, because it didn’t cover enough of the head—it just didn’t seem kippah-ish enough. I ordered prints of the other three from Shapeways. I was immediately told that the multiscale design wouldn’t print because it used wires that were too thin. I shelved that design and went ahead with the Euclidean and inverted models.

The 3D printed inverted kippah. The Jerusalem Post referred to J as “a Jewish youth”, which he definitely is not, either by birth or by practice.

I was quite happy with the results. They fit well, were reasonably thin and pliable, and were visually interesting. But were they kosher? I had no idea if there were laws dictating the design of kippahs. I consulted two learned sources: The Beis, a Torah school in London, and Dr. Mordecai Zeitz, the Rabbi at the school and synagogue to which my family belonged when I was young. Luckily, the experts agree: a kippah is any kind of visible, deliberate head covering, with no restriction on materials or proportion of the head covered. In fact, Rabbi Zeitz even said “a removable hairpiece can serve as a head covering”. Of course, this last option raises a philosophical conundrum. The goal of a hairpiece is to be undetectable. So would only a bad hairpiece be a legal kippah? Conversely, if you see a man in synagogue not obviously wearing his kippah, can you conclude that he’s definitely wearing a toupée?

I’ve been asked a couple of times whether I plan to commercialize these at all. Probably not—even if you could manufacture these via, say, injection moulding, you’d just be wearing a piece of plastic on your head. The 3D printing really does make these interesting somehow. The downside is that if someone wants 200 kippahs for a wedding or a bar mitzvah, I can’t offer any kind of volume discount. But I’m open to new ideas. A friend suggested recreating these designs in laser-cut felt, and then forming the felt into a kippah shape. That would be worth trying.

I was also asked whether I wanted to venture into other 3D printed judaica. A dreidel would be an obvious target, especially with recent research on optimizing 3D models to work as spinning tops. I’ve experimented with a couple of menorah designs in the past, but I’ve never printed any of them; they’re just a bit too expensive at the size and mass needed to be functional. I’ve also thought occasionally about designing a yad, an object that’s much less visible outside the world of observant Jews but which has always fascinated me.

I’ve put an album on flickr with a few additional photos of the kippahs.

Technical details

For a few years now, I’ve been hoping to create a 3D printed hat similar in shape to the panama hat I wear most days in the summer. The hat would consist of a thin latticework of some repeating 2D ornamental pattern, as in my earlier research about semiregular patterns on surfaces, or my related recent Bunny Bunny collaboration with Henry Segerman.

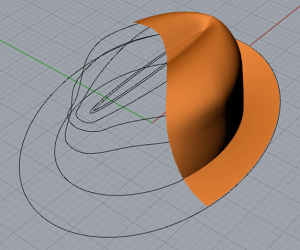

When I began my sabbatical in mid-2013, I knew I finally had an opportunity to think about this project. However, I quickly discovered that the process of developing a hat was going to be more difficult than I had anticipated. First, there’s the shape of the hat itself. I threw together a prototype based on lofting a surface through a sequence of curves, but I don’t have nearly enough 3D modelling experience to get a sense of whether the manufactured result would look lopsided or warped. Then, of course, I would need to parameterize the resulting surface so that I could map copies of the fundamental region of some ornamental pattern onto it. There are many published research papers on this subject (my preferred technique in this context is Spectral Surface Quadrangulation), but every single author I contacted was unable or unwilling to share their implementation, and the topic is far enough from my normal expertise that I could easily flounder for months trying to write the code myself. (If you have an implementation you can share, please let me know!)

Accepting that the full hat project was over my personal horizon, I considered whether I could solve a simpler problem first, and that led me to kippahs. A kippah is just a spherical cap, after all, and it would be easy to project ornamental patterns onto it if the cap is flat enough. I went to a Jewish primary school, and thereby wore a kippah every weekday for many years (in fact, I sometimes wonder whether my instinct to go out with my head covered ultimately derives from this habit). I don’t wear kippahs, but I guess I still had some nostalgia for them.

I wrote a Python script for Rhinoceros that takes some closed planar curves, extrudes them into generalized cones, and intersects the cones with a spherical shell. When the curves are bounded by a circular outline, the resulting object is a spherical cap. The script runs slowly, as it relies heavily on expensive boolean operations on solids, but it was sufficient for my purposes.

The process of carving a pattern into a kippah template: the base curves (left) and the extruded result (right)

I drew the Euclidean and multiscale kippah designs directly in Adobe Illustrator. I wrote a separate program to generate the hyperbolic design, and cleaned up the result in Illustrator. I ran the Euclidean design through a separate program that performs what Dixon calls the antimercator projection and once again cleaned up the result.

There are two obvious parameters involved in choosing the size and shape of a kippah: the radius of the sphere from which it is taken, and the amount of that sphere that it covers. I found some reference online that gave the radius of the sphere that best approximates the adult male head (85mm), and I derived the angular extent of the cap based on the diameters of kippahs I found for sale online (roughly 5.5″, or 139.7mm). I chose a spherical shell with a thickness of 0.75mm (about as thin as Shapeways will print in plastic).

Leave a Reply